Fleet Optimization

Take use of our professional consulting based on 22 years in forklift business, in order to make your next fleet renovation a successful step towards productivity improvement and not a simple repetition of yesterday´s fleet, that does not fit to today´s demands anymore.

A fleet renovation process depends on professional advisement and 100 percent commitment and cannot be driven by employees by the way meanwhile they are occupied 150 percent with their day-to-day work. Outsource your solutions!We stay with you from A to Z.

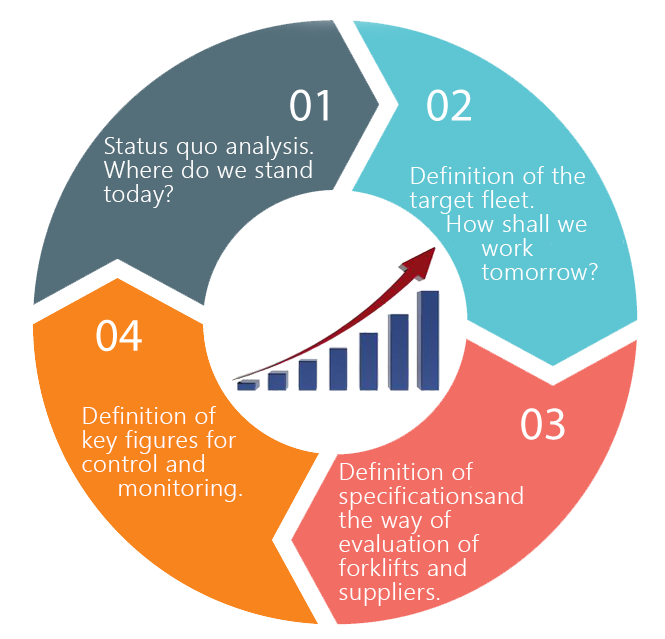

We separate the process of fleet optimization in 4 steps. The 4th and last is at once the base for future actualization or adjustments.

STATUS QUO ANALYSIS

To define the real fleet situation of today it is necessary to analyze all available details before the next step. How many forklift trucks,of which type and in what condition are available at which location. Furthermore we have to check the running variable costs and the real availability of the fleet. Also we have to ask if the todays forklift equipment fulfills the terms of actual ergonomic and security standards. Based on this detailed analysis OUTLETCARRETILLAS & OPTIMIZACION will evaluate your fleet so that the real value can be considered for the productivity calculation. (For more details please have a look at the diagram that is located at the menu bar STATUS QUO ANALYSIS

Target fleet definition: How do we want to work in the future?

A fleet renovation is the opportunity to adjust the forklift fleet to the actual needs. Have changed the dimensions of the loads and pallets to transport? The complete available warehouse height shall me used up to the last mm or the new transport idea is to move the maximum units at floor level? Will we work at 2 shifts for the next season or simply the material flow process has changed at all? Are there processes or parts of a process that could improve productivity with automated guided vehicles? How are we able to improve our CO2 Footprint? Which are the best forklift types to realize our new demands?

DEFINTION of the specifications for the fleet renovation

The definition of specifications for the next fleet actualization is the mirror image of the outcome of the status quo analysis combined with the process ideas for tomorrow. Demands and properties of supplier service and forklift trucks have to be detailed clearly to reduce any doubt what we expect from them.

This refers not only to the minimum properties that a future forklift has to fulfill in terms of ergonomics, safety, energy consumption, technical abilities or the availability of forklift data for further analysis. This refers also to our expectations from the future supplier in terms of energy savings, ISO quality criterias, response times and flexibility.

Each as necessary defined variable must get assigned its specific weight within the comparative calculation of different offers. The most profitable solution is often not the cheapest at first glance.

DEFINITION of key figures to monitor and evaluate progress

The process of fleet renovation does not end with the decision for a new supplier or the delivery of the new forklifts.New processes does not work 100 percent perfect from the first day on and especially at the beginning there used to be opportunities for improvement that in process definition and status quo analysis still has not been visible.Key figures have to be defined to measure and evaluate the success and effectiveness of the change to a new process. With these new key figures a comparison of the new with the old process will be possible and measurable. Examples could be variable fleet costs, accident rate, warehouse capacity increasement o warehouse turnover.

Controlling and measuring of these key figures build the base for a continuous improvement until the next fleet renovation.

Español

Español English

English Deutsch

Deutsch